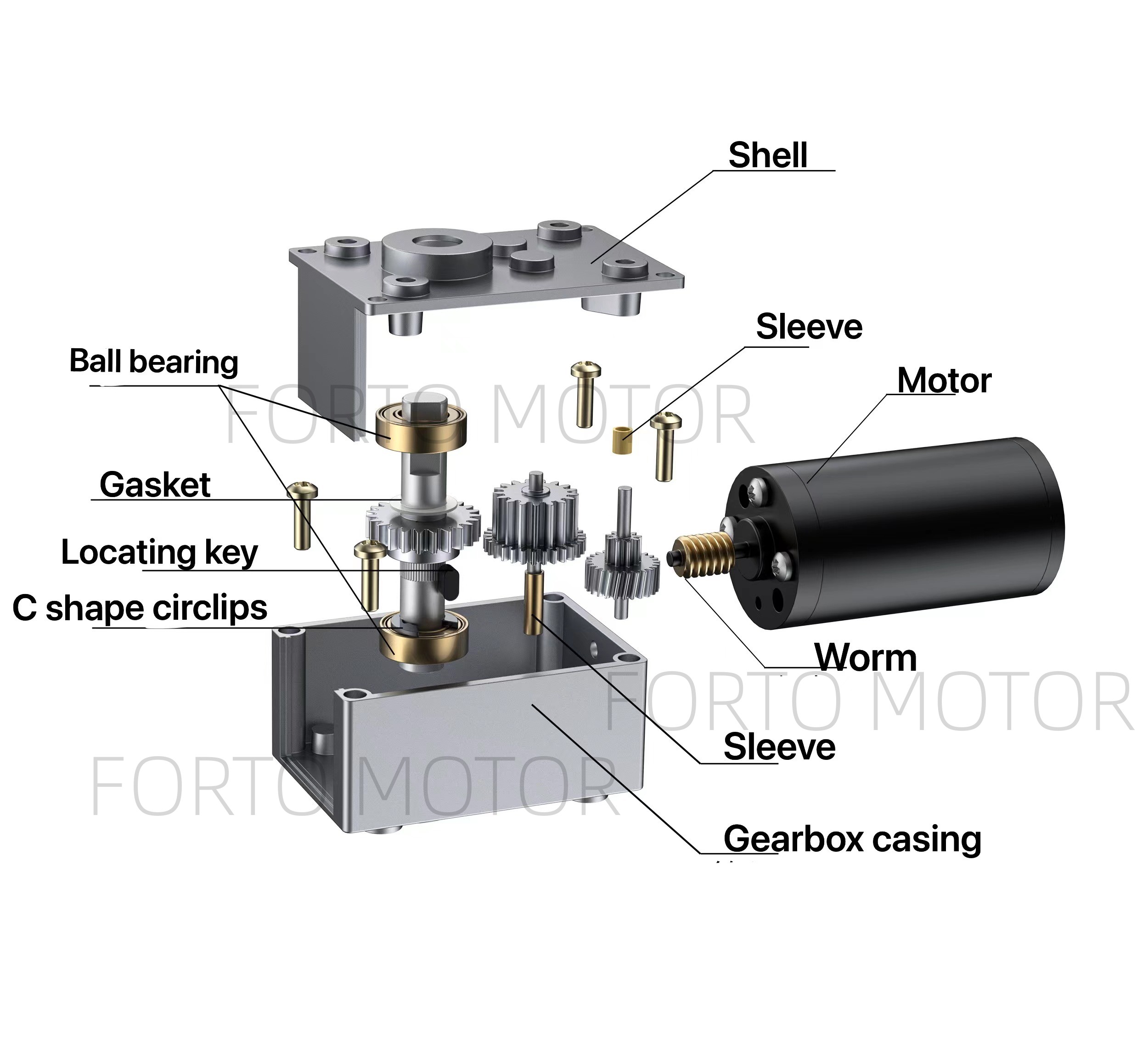

Micro reduction gear motors are widely used in electric curtains. Common types of reduction motors for electric curtains include planetary reduction gear motors, turbine worm gear reduction motors, etc.

The worm gear motor is also a power transmission mechanism that converts speed through gears to reduce the speed of the micro motor to the desired speed and obtain a larger torque. The meshing tooth surfaces of the two wheels of the worm gear reducer are in line contact. , can obtain better meshing effect, and the transmission ratio and load-bearing capacity are also relatively high. The worm gear motor is a spiral transmission. The main form of transmission is tooth mesh transmission, which makes the transmission more stable, with less vibration and low noise. Suitable for use in various electric products that require stability, such as electronic locks, electric curtains, smart homes, etc. The advantage of the worm gear transmission mechanism over other gear transmission structures is its self-locking function. When the worm lead angle of the worm gear transmission mechanism is less than the equivalent friction angle between the meshing gear teeth, the worm gear transmission mechanism will self-lock in the opposite direction. This is also the worm driven mechanism. Worm gear, and the reason why the worm gear cannot drive the worm.

Advantages of electric curtain DC motor worm gear motor: compact mechanical structure, light volume; good heat exchange performance, fast heat dissipation; simple and convenient installation, flexible and convenient, superior performance; large transmission ratio, large torque, high load-bearing capacity; smooth operation and low noise , Long service life; wide range of use, strong applicability, high reliability; with self-locking function. The disadvantage of the electric curtain worm gear reducer is that the transmission efficiency is too low and it is easy to wear during the transmission process. The transmission efficiency is about 60% to 70%.

Post time: Dec-12-2023